Carburetor Adjustments How to Adjust Your Carburetor After Carburetor Rebuild

Posted by admin | 0 comments | 1:45 PMLabels: adjust, adjustments, after, carburetor, how, rebuild, to, your

BMW 635CSi 1985 Electrical Repair

Posted by admin | 0 comments | 5:30 PMLabels: 1985, 635csi, BMW, electrical, Repair

Manufacturer: BMW

Model: 635CSi E24

Year: 1985

Quick Reference Index:

- Power Distribution Box

- Fuse Data

- Diagnostic Connector

- Start

- Fuel Delivery/ Evaporative Control

- Fuel Control/ Idle Speed Control

- Ignition and Charging System

- Wiper/ Washer

- Speedometer/ Gauges/ Warning Indicators

- Active Check Control

- Brake Lining Warning

- Ignition Key Warning Seatbelt Warning

- Headlights/ Fog Lights/ Turn/ Hazard Warning

- Front Park/ Front Maker/ Tail

- Rear Marker/ License/ Trunk

- Cruise Control/ Stop Lights

- Dash Lights/ Interior Lights/ Dash/ Transmission Range

- Back Up/ Transmission Range

- Cigar Lighter/ Glove Box Light/ Digital Clock/ Auto-Charging Flashlight

- Horn/ Sunroof/ Rear Defogger/ Power Windows/ Mirrors/ Central Locking (select)

- Central Locking (control)/ Radio/ Power Antenna/ Auxiliary Fan/ Heater/ Air Conditioning

- Ground Distribution/ Component Locations/ Notes/ Windshield Wipers Jet Heaters

- Splice Locations (Front, Middle, Engine, Rear Harnesses)

Mazda 1968 74 Models Drive Axles Repair Manual

Posted by admin | 0 comments | 10:00 PMLabels: 1968, 74, axles, Drive, Manual, Mazda, models, Repair

- 616 (1971)

- 618 (1972-73)

- 808 (1972-74)

- 1200 (1971-72)

- B1600 (1972-74)

- R100 (1971-72)

- RX-2 (1971-74)

- RX-3 (1972-74)

- RX-4 (1974)

- RE (Rotary Pick-Up) (1974)

|

| AXLE SHAFT ASSEMBLY (EXCEPT PICK-UP) |

|

| AXLE SHAFT ASSEMBLY (B1600 & RE PICK-UP) |

|

| MEASURING PINION HEIGHT |

2) Remove bearing caps and adjusters, then withdraw differential assembly from carrier, making sure side bearing races remain with their respective bearings. If necessary for replacement, use a suitable puller and remove side bearings from gear case. Straighten lock tabs, remove ring gear attaching bolts, and separate ring gear from gear case.

3) On all models except RX-4, drive out differential pinion shaft lock pin with a punch and remove pinion shaft. Rotate pinion gears 90 degrees and remove gears, thrust washers, thrust block (if equipped), and differential side gears. On RX-4 models, remove bolts joining differential case halves and separate case. Remove side gears, thrust washers, pinion gears, and spider.

4) On all models, remove pinion nut and pinion flange. Remove drive pinion and rear bearing assembly, adjusting shims (if equipped), spacer and bearing collar if used). NOTE - It may be necessary to top end of pinion with soft hammer to remove from carrier. Remove front oil seal and withdraw front pinion bearing. Using a press, remove rear bearing from drive pinion, then lift off pinion adjusting shim. If necessary for replacement, use a drift punch and remove pinion bearing races from carrier.

|

| MAZDA REAR AXLE ASSEMBLY |

REASSEMBLY AND ADJUSTMENT

Drive Pinion Depth - 1) NOTE -The use of a suitable dial indicator assembly (49 0727 570) and pinion gauging set (49 0305 555, all exc. pick-up; or 49 0603 555A, B1600 and RE pick-up) is required for this procedure. Install dial indicator on gauge body, place gauge body on a surface plate, and preload indicator .040-.120" (1-3 mm). When preloaded, turn outer ring of indicator assembly to "zero" gauge.

2) Make sure differential bearing bores are free of dirt and burrs, then install drive pinion, dummy bearing, and original pinion depth shim into carrier. Place gauge block on pinion and position indicator assembly on block so button of indicator contacts lowest portion of differential bore.

3) Record the amount indicator moves in a "+" (plus) or "-" (minus) direction from zero. Remove gauging assembly and pinion from carrier. Check rear face of pinion for the machining correction figure. If pinion is marked "+" (plus), SUBTRACT amount specified on pinion from dial indicator reading; if marked "-" (minus), ADD amount to indicator reading. NOTE - Figures on pinion are hundredth millimeters.

4) Place dummy pinion and rear pinion bearing on surface plate and compare heights. If pinion bearings is higher than dummy bearing, SUBTRACT difference from dial indicator reading, if pinion bearing is lower than dummy bearing, ADD amount to indicator reading.

5) Select correct pinion depth adjusting shim to be used for reassembly by adding or subtracting the amount determined in steps 2), 3), and 4) from the thickness of the original pinion depth shim used during gauging process. Position correct shim on pinion and install pinion bearing. Shims are available in the following thicknesses for all models except RX-4:

Identification Mark Thickness In. (mm)

08....................................................... .121 (3.08)

11....................................................... .122 (3.11)

14....................................................... .124 (3.14)

17....................................................... .125 (3.17)

20....................................................... .126 (3.20)

23....................................................... .127 (3.23)

26....................................................... .128 (3.26)

29....................................................... .130 (3.29)

32....................................................... .131 (3.32)

35....................................................... .132 (3.35)

38....................................................... .133 (3.38)

41....................................................... .134 (3.41)

44....................................................... .135 (3.44)

|

| SOLID BEARING PRELOAD SPACER AND SHIMS |

For RX-4 models, the following thickness shims are available

Identification Mark Thickness In. (mm)

52....................................................... .139 (3.52)

55....................................................... .140 (3.55)

58....................................................... .141 (3.58)

61....................................................... .142 (3.61)

64....................................................... .143 (3.64)

67....................................................... .145 (3.67)

70....................................................... .146 (3.70)

73....................................................... .147 (3.73)

Pinion Bearing Preload (W/ Solid Bearing Spacer) - 1) Position drive pinion and rear bearing assembly into carrier, then install bearing spacer and preload shims onto pinion. Install front pinion bearing and pinion flange (do not install oil seal at this time). Install pinion nut and tighten to 110 ft. lbs. (15 mkg) on 1200 models or 130 ft. lbs. (18 mkg) on R-100 models.

2) Using a torque wrench installed on pinion nut, measure turning torque of drive pinion through at least one full revolution. If preload is greater than specified (see Axle Assembly Specifications), a thicker shim or longer bearing spacer is required; if preload is less than specified, a thinner shim or shorter bearing spacer is required. Shims and spacer are available in the following thicknesses and lengths:

Identification Mark Thickness/Length In. (mm)

|

| INSTALLING COLLAPSIBLE BEARING SPACER |

4..................................................... .013 (.34)

6..................................................... .014 (.36)

8..................................................... .015 (.38)

Spacer (1200 Model Only)

10................................................... 1.658 (41.10)

18................................................... 1.661 (41.18)

26................................................... 1.664 (41.26)

34................................................... 1.668 (41.34)

Spacer (R-100 Model Only)

60................................................... 2.149 (54.60)

68................................................... 2.152 (54.68)

76................................................... 2.155 (54.76)

84................................................... 2.159 (54.84)

|

| INSTALLING PINION SHAFT & LOCK PIN |

Pinion Bearing Preload (W/Collapsible Bearing Spacer) - 1) Position drive pinion in carrier and install bearing spacer. Place front pinion bearing in position on pinion gear, hold gear fully forward, and drive bearing over pinion until seated. Apply grease to lip of pinion by tapping with a soft hammer. Install pinion washer and nut. Before tightening nut (when pinion preload is zero), check oil seal drag using a torque wrench. Tighten pinion nut as follows:

Application Ft. Lbs. (mkg)

808 (W/1300 cc)................................... 87 (12)

|

| INSTALLING DIFFERENTIAL ASSEMBLY |

B1600, RE (Rotary Pick-Up)................... 145(20)

All Others.............................................. 94(13)

2) With nut tightened, check preload using a torque wrench mounted on pinion nut. If preload is not as specified (see Axle Assembly Specifications), continue tightening nut and checking preload until specified preload is obtained. CAUTION - Preload builds quickly. Nut should be tightened a little at a time and preload checked after each slight amount of tightening.

Case Assembly - 1) On all models except RX-4, install a thrust washer on each differential side gear and install into case. Through openings in gear case, insert pinion gears exactly 180 degrees opposite each other. Rotate pinion gears 90 degrees so holes in gears line up with pinion shaft holes in gear case. Insert pinion shaft through case and pinion gears.

|

| ADJUSTING BEARING PRELOAD (CASE SPREAD) |

3) On all models, check backlash between side gears and pinion gears. Backlash should be less than .004" (.1 mm); if not, install selective thrust washers to bring backlash within specifications. Washers are available in thicknesses of .063" (1.6 mm), .067" (1.7 mm), .071" (1.8 mm), .079" (2.0 mm), .083" (2.1 mm), and .087" (2.2 mm). NOTE - Always use some thickness thrust washer for both side gears.

4) If equipped with thrust block, remove pinion shaft, install thrust block, and reinstall pinion shaft. On all models except RX-4, drive lock pin into case to secure pinion shaft. Using a punch, shake lock pin into case to secure pinion shaft. Using a punch, stake lock pin hole to prevent pin from working loose. On all models, mount ring gear on case, then install and tighten ring gear attaching bolts. If removed, instal differential side bearings.

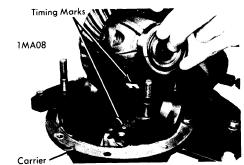

4) If equipped with thrust block, remove pinion shaft, install thrust block, and reinstall pinion shaft. On all models except RX-4, drive lock pin into case to secure pinion shaft. Using a punch, shake lock pin into case to secure pinion shaft. Using a punch, stake lock pin hole to prevent pin from working loose. On all models, mount ring gear on case, then install and tighten ring gear attaching bolts. If removed, instal differential side bearings.Backlash & Side Bearing Preload - 1) Place differential case assembly into carrier making sure timing marks on ring and pinion gears are aligned. Install bearing adjusters and bearing caps, then tighten bearing cap nuts or bolts finger tight. Turn adjusters with a suitable spanner wrench (49 0259 720) until bearing end play is eliminated and some backlash exists between ring gear and pinion. Slightly tighten one bearing cap nut or bolt on each side carrier.

2) Mount a dial indicator to carrier flange so button of indicator contacts of the ring gear teeth at a right angle then check backlash between ring and pinion gears. Using the spanner wrench, turn both bearing adjusters equally until backlash is as specified in Axle Assembly Specifications.

3) Differential bearing preload (case spread) is obtained by tightening both bearing adjusters equally. Tighten adjusters until the distance between pilot section of side bearing caps in as specified in Axle Assembly Specifications. Tighten bearing cap nuts or bolts, then recheck backlash adjustement. Make a gear tooth pattern check to insure correct assembly, then install adjuster lock plates on bearing caps.

Nissan Sentra B13 1994 Repair Manual

Posted by admin | 0 comments | 3:00 AMLabels: 1994, b13, Manual, Nissan, Repair, sentra

Model: Sentra B13 Series

Year: 1994

Engine: 1.4 L GA14DE I4

1.6 L GA16DE I4

2.0 L SR20DE I4

Quick Reference Index:

- General Information

- Maintenance

- Engine Mechanical

- Engine Lubrication and Cooling Systems

- Engine Control System

- Accelerator Control, Fuel and Exhaust Systems

- Clutch

- Manual Transmission

- Automatic Transmission

- Transfer

- Propeller Shaft and Differential Carrier

- Front Axle and Front Suspension

- Rear Axle and Rear Suspension

- Brake System

- Steering System

- Restraint System

- Body and Trim

- Heater and Air Conditioner

- Electrical System

- Alphabetical Index

1970 73 Capri All Models Wheel Alignment

Posted by admin | 0 comments | 6:15 AMLabels: 1970, 73, alignment, all, capri, models, wheel

TIRE INFLATION (COLD)

Before attempting to check or adjust wheel alignment, ensure that tires are properly inflated. Refer to manufacturers specifications located on right hand sun visor.

CASTER

All Models - Caster is nonadjustable. If not within specifications, check front suspension for damage. Repair or replace parts as necessary.

CAMBER

All Models - Camber is non adjustable. If not within specifications, check front suspension for damage. Repair or replace parts as necessary

TOE-IN

All Models - Position wheels in straight ahead position and loosen tie rod end lock nut and clips securing bellows. To adjust toe-in, rotate tie rods until specifications are within limits. Tighten lock nuts and secure clips. Tie rods should be equal within 1/4".

The New Improved and Re designed Auto Repair Savings My Special Links!

Posted by admin | 0 comments | 10:30 AMLabels: and, auto, designed, improved, links!, my, new, re, Repair, savings, special, the

BMW 5 Series Service Manual

Posted by admin | 0 comments | 3:30 PMLabels: 5, BMW, Manual, Series, service

Model: 5-Series 525i, 530i, 535i, 540i, including touring,

Year: 1989, 1990, 1991, 1992, 1993, 1994, 1995

Quick Reference Index:

- General Data and Maintenance

- Engine

Engine-General, Engine Removal and Installation, Cylinder Head Removal and Installation, Cylinder Head and Valvetrain, Camshaft Timing Chain, Camshaft Timing Belt, Lubrication System, Ignition System--DME, Battery, Starter, Alternator, Fuel Injection--DME, Fuel Tank and Fuel Pump, Radiator and Cooling System, Exhaust System - Transmission

Transmission-General, Clutch, Manual Transmission, Automatic Transmission, Gearshift Linkage, Driveshaft - Suspension, Steering and Brakes

Suspension, Steering and Brakes - General, Front Suspension, Steering and Wheel Alignment, Rear Suspension, Final Drive, Brakes - Body

Body-General, Fenders and Engine Hood, Doors, Trunklid, Tailgate - Body Equipment

Exterior Trim Bumpers, Door Windows, Interior Trim, Central Locking, Seats, Sunroof - Electrical System

Electrical System - General, Fuses and Relays, Wipers and Washers, Switches and Electrical Accessories, Instruments, Exterior Lighting, Heating and Air Conditioning, Radio - Equipment and Accessories

Seat Belts, Air Bag System (SRS) - Electrical Wiring Diagrams

Car Specifications

Posted by admin | 0 comments | 8:00 PMLabels: car, specifications

This can be found on the schroud above the fan or on the hood it self. The mechanics will have to double check this while doing the repairs anyways so dont worry to much.

A dishonest mechanic can use this first conversation with you to determine if you are aware of your vehicles information. Their thinking is if you dont know your vehicles year make and model and engine size then you dont know really whats under your hood. So if all possible, have this information stored where you can have access to it when needed, like either your computer,

In one of my earlier blogs I mentioned to ask to see your old parts when they are finished. Even know you dont know what your looking at, this gives the mechanics a sence that you are a very careful shopper!

If you havent got your own pocket scanner from Amazon you should plan on getting one real soon. I used it already 3 times in the past 3 months! Once for my car and 2 other times looking at friends and families vehicles. Somthing about the weather change brings on all kinds of car problems. Being able to bring in your own codes to your mechanic also shows him you care about your car and less likely to be scammed also.

So input your vehicles information some wheres so you can have it handy! Happy Driving!

Porsche 986 Boxter Owners Manual

Posted by admin | 0 comments | 11:30 PMLabels: 986, boxter, Manual, Owners, porsche

Model: 986

Table of contents:

- Controls and instruments

- Shifting Gear

- Mobile Roofs

- Maintenance

- Car Care

- Practical Tips

- Emergency Service

- Vehicle Identification

- Technical Data

- Index

1974 Capri Wheel Alignment

Posted by admin | 0 comments | 3:15 AMLabels: 1974, alignment, capri, wheel

TIRE INFLATION (COLD)

Before attempting to check or adjust wheel alignment, make sure that tires are properly inflated. Refer to manufacturers specifications, located inside glove box door.

CASTER

All Models - Caster is nonadjustable. If not within specifications, check front suspension for damage. Repair or replace parts as necessary.

CAMBER

All Models - Camber is non adjustable. If not within specification, check front suspension for damage. Repair or replace parts as necessary.

TOE-IN

All Models - Position wheels in straight-ahead position and loosen tie rod end lock nut and clips securing bellows. To adjust toe-in, rotate tie rods until specifications are within limits. Tighten lock nuts and secure clips. Tie rods lengths should be equal within 1/4".

Arrow 1976 77 Drive Axles Repair Manual

Posted by admin | 0 comments | 7:45 AMLabels: 1976, 77, arrow, axles, Drive, Manual, Repair

- Arrow

- Colt

|

| FIG. 1 MEASURING AXLE SHAFT DEFLECTION |

|

| FIG. 3 REMOVING DIFFERENTIAL GEAR HOUSING |

|

| FIG. 6 REMOVING DRIVE PINION FRONT BEARING OUTER RACE |

|

| FIG. 7 EXPLODED VIEW OF COLT SEPARATE HOUSING REAR AXLE ASSEMBLY |

|

| FIG. 9 MEASURING CLEARANCE BETWEEN SIDE BEARING AND GEAR CARRIER |

Pantera 1973 74 Wheel Alignment Repair Guide

Posted by admin | 0 comments | 1:15 PMLabels: 1973, 74, alignment, guide, pantera, Repair, wheel

TIRE INFLATION (COLD)

Before attempting to check or adjust wheel alignment, make sure tires are properly inflated. Refer to manufacturers specifications given in owners manual.

RIDING HEIGHT

NOTE - Vehicle must be loaded to simulate normal road condition, before attempting to check or adjust wheel alignment.

CASTER

Caster angle is not adjustable. If caster angle is not within specifications, inspect suspension system for wear or damage and repair or replace components as necessary.

CAMBER

Front - With normal loaded condition simulated, measure camber angle. If adjustment is necessary, loosen bolts on upper control arm ball joint. Move ball joint in or out to obtained specified angle. Tighten bolts.

Rear - If rear camber angle is not to specifications, adjust by adding or removing an equal number of shims between lower control arm attaching bracket and the frame. NOTE - An equal number of shims must be added or removed at both attaching brackets.

TOE-IN

Front - Set wheels in straight-ahead position and measure toe-in. If adhustment is necessary, loosen lock nuts on steering link (tie rods) adjusting sleeves. Rotate each sleeve on equal amount until correct toe-in is obtained. NOTE - After adjustment, both steering links (tie rods) should be of equal length.

Rear - Back vehicle onto alignment machine, and note that a toe-out condition will be indicated. If adjustment is necessary, loosen lower control arm attaching bracket both and insert horseshoe shims behind lower control arm attaching bracket. NOTE - After adjusting toe-in, thickness of shims should be about equal on each side of vehicle.

Tax Date

Posted by admin | 0 comments | 4:30 PMLabels: date, tax

Tax Date 4f4cebdd02a311330441181

Results for Tax Date

File Form 945 To Report Held Income Tax For 2011. This Due Date Ap-income Tax Withheld For 2011 On All Nonpayroll Second Quarter Plies Only If You Deposited The Tax For The

http://www.irs.gov/pub/irs-pdf/p509.pdfDeadline For Filing Forms P9d, P11d, P11d(b), Or Substitutes For The Tax Year Ending 5 April 2011. 6. Last Date For Giving A Copy Of The 2010-11 Forms P9d, And Forms

http://www.hmrc.gov.uk/agents/tax-deadlines.pdfCalifornia City And County Sales And Use Tax Rates N ***october*2011 Page 4 District Taxes, Rates, And Effective Dates* Tax Area District Name And Initials Rate Effective Date End

http://www.boe.ca.gov/sutax/pdf/districtratelist.pdfIf The Qsub Is Acquired During The Taxable Year, The Qsub Annual Tax Is Due With The S Corporations Next Estimated Tax Payment After The Date Of The Qsub Election.

http://www.ftb.ca.gov/forms/2011/11_100esins.pdf2012 Property Tax Calendar * If A Due Date Falls On A Saturday, Sunday, Or Legal Holiday, That Due Date Becomes The Next Business Day. (rcw 1.12.070) January 1

http://dor.wa.gov/Docs/Pubs/Prop_Tax/PropCal.pdfFor Most Individual Income Tax Filers, This Date Is 12-2011. Fiscal Year Filers: See Supplemental Instructions For Standard Fiscal Mbt Filers On Page 145 Of Form

http://michigan.gov/documents/4_144975_7.pdfApr 30 South Dakota Re Tax Bills Due - 1st Half Installment. Apr-may Tennessee Re Value Notices Issued - 40% Assmt. Ratio. Apr - May Texas Re Value Notices Issued Apr

http://www.transporttax.com/documents/PropertyTaxDates.pdfArkansas Excise & Income Tax Due Dates 2010 Tax Calendar For Small Businesses

http://www.dfa.arkansas.gov/Documents/dueDateCalendar.pdfLine 19 (penalty) - If This Tax Report And Remittance Is Not Postmarked Within 15 Calendar Days Of The Due Date, A 10% Penalty Is Due. Multiply The Tax Amount On Line 16

http://www.tax.ok.gov/btforms/13-23.pdfWest Virginia State Tax Department 2012 Tax Calendar Org. 1/12 Due Date Form Form Title Comments January 10 Wv/brw-01 Brewer/importer/manufacturer Beer

http://www.state.wv.us/taxrev/publications/taxCalendar.pdfIr 328 February 2011. Ir 328 February 2011 Employer Deductions (edf/ir 345) Form And Payment Due And Employer Monthly Schedule (ems/ir 348) Due Note: This Calendar

http://www.ird.govt.nz/resources/7/d/7d8ab880423855ca901a9d82245c33b7/ir328.pdfTax Payments, Year-to-date Payroll (9/4/2008) Page 1 Of 8 Tax Payments Checklist (yeartodate Payroll) Important : Before You Enter Tax Payments In The Enter

http://http-download.intuit.com/http.intuit/CMO/payroll/support/PDFs/Misc/YTD_Tax_Checklist.pdf1 Maine Tax Alert A Publication Of Maine Revenue Services For Tax Professionals Volume 21, No. 6 September, 2011 (2 Nd Issue) Public Communications Tel: (207) 626

https://maine.gov/revenue/publications/alerts/2011/TASep2011_2_Vol21_Iss6.pdfPay The Tax After The Due Date, A Penalty Is Assessed. The Penalty Is 6% Of The Tax Due For Each Month Or Fraction Of A Month, Not To Exceed 30%.

http://www.tax.virginia.gov/taxforms/Business/Withholding%20Tax/VA-%205%20Quarterly.pdfAny Additional Tax Due Must Be Paid On Or Before The Due Date Of The Monthly Tax Return. All Employers Subject To The Requirement Of Quarter-monthly Filing Must File And

http://dor.mo.gov/forms/efile.pdfHowever, If, At A Later Date, You Need To Establish The Date You Filed*or*paid*your*tax,*you*cannot*use*the*date*recorded*by*a* Private Delivery Service Unless You Used A

http://www.tax.ny.gov/pdf/current_forms/ct/ct5i.pdfFrx 0600202 000 L. Frx0002-05-1999-bt Form 200 Revised 6-2006 Oklahoma Annual Franchise Tax Return A. Taxpayer Fein B. Reporting Period C. Due Date 1 2 3 4 5 6 7

http://www.tax.ok.gov/oktax/btforms/200long-06.pdfAll Wages Paid During The Calendar Quarter Should Be Reported On The Same Form G-7/schedule B Listing The Tax Withheld For Each Pay Date Of The Quarter.

https://etax.dor.ga.gov/taxguide/TSD_Employers_Withholding_Tax_Guide_2011.pdfBMW 850i 1991 Electrical Repair

Posted by admin | 0 comments | 8:15 PMLabels: 1991, 850i, BMW, electrical, Repair

Manufacturer: BMW

Model: 850i E31

Year: 1991

Quick Reference Index:

- Introduction/ Symbols

- Power Distribution and Fuse Chart

- Fuse Details, Ground Distribution

- Data Link

- Engine Control System (DMEM1.7, 12-Cylinder M70)

- Electronic Throttle Control System (EML 12-Cylinder)

- Start and Charging System

- Power Assist Steering (Servotronic)

- Electronic Shock Absorber Control (EDC III+)

- Electronic Transmission Control (EGS)

- Supplemental Restraint System (Airbag)

- Slip Control (ABS)

- Power Mirrors

- ZKE: Door Lock Heating (TSH), Central Locking (ZV), Power Windows (FH)

- Power Seats and Lumbar Support. Heated Seats

- Power Sunroof (SHD), Central Body Electronics (ZKE IV)

- Horn, Drive-Away Protection (EWS II)

- Wiper/ Washer Module (WWM)

- Headlight Washer (SRA)

- Windshield Washer Jet Heaters

- Instrument Cluster, Clock, Light Switch Details Headlights, Fog Lights

- Turn/ Hazard Lights/ Park/ Tail/ Underhood Lights

- License Plate/ Luggage Compartment Lights

- Back up Lights, Brake Lights, Interior Lights, Interior Accessories, Crash Control Module

- Rear Window Defogger, Integrated Heating-Climate Control

- Radio/ CD Player (Provisions)/ HIFI

- Cellular Telephone (Provisions)

- Cruse Control (Tempomat), Anti-theft System (ALPINE)

- Board Computer (BC-LOW)

- Component Location Chart and Views

- Splice Location Views, Connector Views

Nissan Pathfinder WD21 1994 Repair Manual

Posted by admin | 0 comments | 5:15 PMLabels: 1994, Manual, Nissan, pathfinder, Repair, wd21

Model: Pathfinder WD21 Series 1st Generation

Year: 1994

Engine:2.4 L Z24i I4106 hp (79 kW)

2.4 L KA24E I4 140 hp (100 kW)

3.0 L VG30i V6 145 hp (108 kW)

3.0 L VG30E V6 153 hp (114 kW)

2.7 L TD272 I4 Diesel 84 hp (63 kW)

2.7 L TD27T2 I4 Turbodiesel 99 hp (74 kW)

2.7 L TD27T4 I4 Turbodiesel 113 hp (84 kW)

Quick Reference Index:

- General Information

- Maintenance

- Engine Mechanical

- Engine Lubrication and Cooling Systems

- Engine Fuel and Emission Control Systems

- Accelerator Control, Fuel and Emission Control Systems

- Clutch

- Manual Transmission

- Automatic Transmission

- Transfer

- Propeller Shaft and Differential Carrier

- Front Axle and Front Suspension

- Rear Axle and Rear Suspension

- Brake System

- Steering System

- Body

- Heater and Air Conditioner

- Electrical System

- Alphabetical Index

Mazda Millenia 1996 Workshop Manual

Posted by admin | 0 comments | 4:00 PMLabels: 1996, Manual, Mazda, millenia, Workshop

Model: Millenia

Year: 1996

Contains the following information and repairs for:

- General Information

- Engine (KJ and KL)

- Lubrication System

- Cooling System

- Fuel Emissions and Control Systems

- Engine Electrical System

- Automatic Transaxle (GF4A-EL and LJ4A-EL)

- Front and Rear Axles

- Steering System

- Braking System and Traction Control System

- Wheels and Tires

- Suspension

- Body

- Body Electrical System

- Heater and Air Conditioning

Audi 80 1992 Electrical Diagrams

Posted by admin | 0 comments | 1:30 PMLabels: 1992, 80, audi, diagrams, electrical

Model: 80

Year: 1992

Quick Reference Index:

- Self-Diagnosis

- Starter

- Current Supply

- Gauges

- Instruments

- Radio

- 2-Way Radio

- Telephone

- Windscreen Wipers

- Wash Sysetm

- Lights, Lamps, Switches - Interior and Exterior

- Wiring

Mazda RX 7 1993 Owners Manual

Posted by admin | 0 comments | 11:00 AMLabels: 1993, 7, Manual, Mazda, Owners, rx

Model: RX-7

Year: 1993

Table of Contents

|

| Mazda RX-7 Interior |

- Your Vehicle at a Glance

- Knowing Your Mazda

- Protecting Your Mazda

- Driving Your Mazda

- In Case of Emergency

- Appearance Care

- Maintenance

- Customer Information (Including Information on How to Report Defects)

- Specifications

- Index

Auto Repair Beware of Skeezy Technicians

Posted by admin | 0 comments | 8:45 AMLabels: auto, beware, of, Repair, skeezy, technicians